Understanding how light, lasers, and a bit of aerospace science help us measure methane with exceptional accuracy.

Read time: 5 minutes

Detecting Methane with Light

How do you “see” a gas that is invisible to the naked eye?

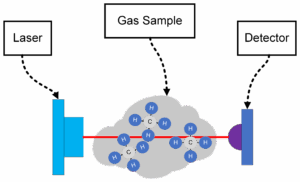

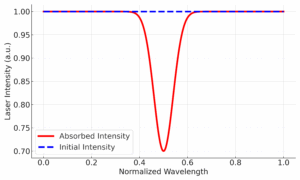

That’s the challenge our team set out to solve with the SeekIR® sensor. Methane is colorless and odorless, but it interacts with specific wavelengths of light in a very predictable way. When laser light passes through a plume of methane, any methane molecules in the way will absorb some of the light. By measuring how much light gets through, we can determine how much methane was present. This technique is called absorption spectroscopy, and it allows us to measure methane with exceptional precision, down to parts per billion. That’s like spotting a single drop of ink in an Olympic-size swimming pool.

This optical approach is powerful because it’s non-contact and extremely fast, making it ideal for mobile platforms like drones.

The Basics of Absorption Spectroscopy

Imagine shining a flashlight through a fog. Some of the light makes it through, and some gets absorbed by the tiny water droplets. By measuring how much light is absorbed, you can learn something about what’s in the fog.

In our case, instead of a flashlight, we use a Tunable Diode Laser (TDL) that emits light at a specific wavelength that methane molecules are known to absorb. And instead of fog, we’re looking through air that may or may not contain methane. If methane is present, it will absorb some of the laser light, and our detector on the other side will see a dip in the signal.

This process is described by the Beer-Lambert Law, a physics equation that helps us calculate exactly how much methane is in the air based on how much light was absorbed. This is the same principle used in laboratories, but we’ve miniaturized and ruggedized it for use in real-world environments on unmanned aerial systems (UAS).

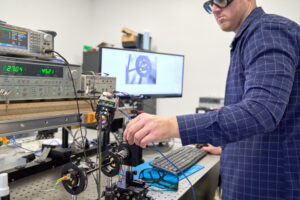

Building a Better Sensor

Not all sensors are created equal. While laser spectrometers exist on the market, the SeekIR® sensor was engineered for maximum sensitivity and durability, combining aerospace-grade optics with field-ready design.

To boost sensitivity, the SeekIR® sensor uses a special design called a Herriott Cell, a key feature to the design. Think of it like a hall of mirrors, our laser bounces back and forth between two highly reflective surfaces, giving it a longer path to interact with any methane molecules in the air. The longer the path, the more chances we have to detect even tiny amounts of gas.

We also use a technique called Wavelength Modulation Spectroscopy (WMS). This method “tunes” the laser rapidly across a small range of wavelengths, helping us cut through background noise and measure only what we care about. It’s like tuning a radio to the exact frequency of your favorite station while filtering out static. This means our readings are both more accurate and more robust, even when environmental conditions aren’t ideal.

Built for Real-World Conditions

Sensitive scientific instruments are usually delicate or don’t hold up in the field, but this one is different.

We perform a rigorous multi-point calibration of each sensor in our laboratory, allowing it to maintain high accuracy across a broad dynamic range of methane concentrations. This step is critical to ensure the sensor produces consistent, quantitative data, regardless of whether it’s detecting a small background enhancement or a significant leak event.

Following calibration, each sensor is placed in an environmental chamber where it’s subjected to controlled humidity conditions ranging from 0% to 95% relative humidity (RH). This ensures the sensor’s optical and electronic systems remain stable even in highly variable weather conditions.

The sensor’s robustness is further confirmed through temperature validation tests between -20°C and 55°C, simulating the harshest real-world environments, from frozen oilfields to tropical biogas facilities. These extremes are not hypothetical—they reflect the demanding conditions our clients face across global field deployments.

Additionally, it’s ruggedized for the harshest environments. The ruggedization is verified through the shock and vibration testing completed at our factory. Confirming it’s ready to operate around the world in a variety of winds, temperatures, and high altitudes without missing a beat.

Why Precision Matters

In emissions monitoring, small errors can lead to big consequences.

When you’re trying to quantify emissions that can change rapidly with weather or equipment conditions, precision is everything. An error of just a few parts per million could mean the difference between reporting a small leak or missing a much larger one. Operators may delay repairs, regulators may receive incomplete data, and companies may miss emissions targets. That’s why precision isn’t just a nice-to-have, it’s a requirement.

Once calibrated in the factory, our laser-based sensor doesn’t require recalibration in the field and maintains its accuracy over time even after extended use. That gives us and our customers confidence in the data we collect, whether it’s being used for regulatory reporting, sustainability goals, or leak detection and repair (LDAR) programs.

A Foundation for Smarter Decisions

By precisely measuring methane in the air, the SeekIR® sensor forms the backbone of our measurement system. It tells us when methane is present, how much there is, and helps guide our drone flights to find the source.

And while the technology might be based on sophisticated optics and physics, the goal is simple: give companies a reliable way to see what was once invisible—and take action.

In our next post, we’ll explore how methane behaves in the atmosphere and why mobility (like flying a drone) is key to understanding emissions in three dimensions.

Stay tuned for the next post in our series: “Capturing the Invisible – Methane Plumes in Motion.”

Want to learn how precise methane detection helps reduce emissions?

Contact Us to discover how SeekIR® can support your environmental goals.

References

Hanson, R. K., Spearrin, R. M., & Goldenstein, C. S. (2016). Spectroscopy and Optical Diagnostics for Gases (Vol. 1). Springer. https://link.springer.com/book/10.1007/978-3-319-23252-2

Webster, C. R. (2005). Measuring methane and its isotopes 12CH₄, 13CH₄, and CH₃D on the surface of Mars with in situ laser spectroscopy. Applied Optics, 44(7), 1226–1235. https://doi.org/10.1364/AO.44.001226

Corbett, A., & Smith, B. (2022). Study of a Miniature TDLAS System Onboard Two Unmanned Aircraft to Independently Quantify Methane Emissions from Oil and Gas Production Assets and Other Industrial Emitters. Atmosphere, 13(5), 804. https://doi.org/10.3390/atmos13050804

NASA Spinoff (2019). Methane Detector Sniffs Out Leaks. NASA Technology Transfer Program. https://spinoff.nasa.gov/Spinoff2019/ps_7.html