Biogas and biomethane are renewable energy sources produced from the decay of organic matter such as plants, food waste, and animal waste. A leading North American biogas operator, recognizing the high value of these products in terms of both raw output and carbon credits, partnered with SeekOps to benchmark their sites for methane emissions and pinpoint leaks for targeted repairs.

Key Goals

- Detect, localize, and quantify methane emissions to prioritize operational repairs to maximize revenue from biogas production and carbon credits

- Benchmark total site emissions across selected North American biogas facilities

- Ensure emissions abatement through repeat surveys to assess repair effectiveness

Specific Circumstances

Biogas facilities contain a complex array of small assets, including influent systems, separators, anaerobic digesters (both concrete and membrane), utilities, flare stacks, and gas upgrading stations. These compact layouts pose unique challenges for emissions monitoring, as traditional methods like aircraft and satellite monitoring lack the necessary detail for such small-scale assets.

Additionally, the facilities need a cost-effective, efficient, and safe method to identify, localize, and quantify multiple potential leak sources across their sites. The operator also faced pressure to maximize their revenue from both biogas production and carbon credits, making accurate emissions detection and quantification crucial in ensuring asset integrity.

What We Did

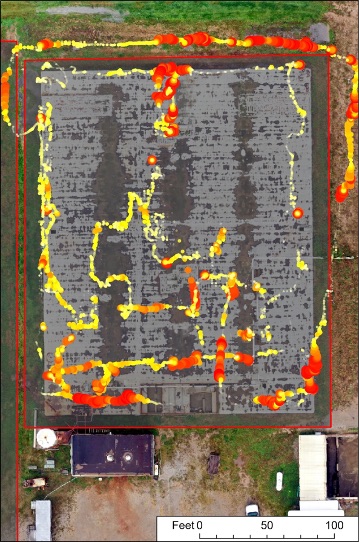

SeekOps implemented an emissions monitoring strategy tailored to the unique needs of the biogas facilities. We began by capturing high-resolution orthomosaic images using drones to contextualize emissions across the facility. Our proprietary SeekIR® sensor, capable of detecting methane at part-per-billion levels, was mounted on enterprise-grade drones and deployed for detailed emissions profiling. We conducted drone flights downwind of specific equipment groups.

In areas where emissions were detected, our team used the sensor in handheld mode to further refine leak locations, tagging them for investigation and repair. To ensure consistent monitoring, we established waypoints at the facility, enabling fully automated, repeatable surveys for swift follow-up and accurate comparisons of pre- and post-repair emissions.

Throughout the process, we compiled reports including benchmark emissions, emissions heatmaps, emissions by equipment group, and specific areas needing repair. After repairs were completed, we conducted additional automated flights to compare against initial benchmarks, producing final reports that showed post-repair emissions numbers and quantified changes attributed to repairs. This approach allowed for efficient, safe, and cost-effective emissions monitoring while providing the detailed data necessary for the client to make informed decisions about repairs and optimize their operations.

Outcome

SeekOps’ surveys and follow-up assessments yielded significant results for the biogas facility:

- Discovered significantly more leaks than initially expected, highlighting the effectiveness of our high-sensitivity sensor

- Identified multiple leak paths, including digestor insulation junctions, agitators, gas upgrading hoses, flanges, and scrubbers

- Revealed that effluent ponds were exhibiting high emissions, indicating inefficient digestion processes

- Detected a critical issue where a flow meter was venting nearly 25% of production, leading to substantial product loss

- Enabled the client to save over $600,000 in lost revenue due to early leak detection

- Achieved a 71% average decrease in emissions following repairs identified by SeekOps’ surveys

These outcomes demonstrate the value of SeekOps’ precise emissions monitoring service in improving operational efficiency, reducing methane emissions, and maximizing revenue for biogas facilities.